HemmingMachine

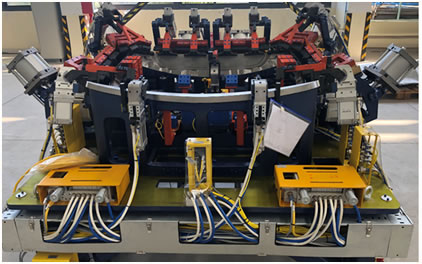

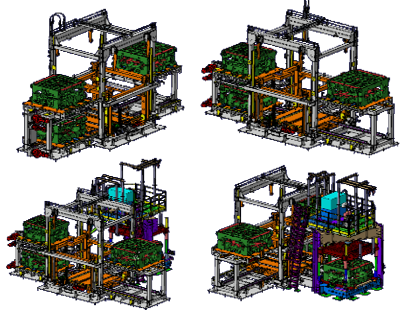

车身车间的压机应用于四门两盖的包边工艺,通过压机将钣金件的预留边向内侧翻折,

而将外板和内板整合成一体。截至2023年底,我们总共交付9台油压压机。

压机主要由以下几部分组成:

1. 机运系统:负责运送钣金件;

2. 模具:包括上模和下模,用于将钣金件压制成型;

3. 液压系统:用于驱动上模上升、下降、加压;

4. 模具更换系统:负责在切换车型时更换模具。

The hemming machine in bodyshop applies hemming process on doors.

The machine folds the reserved edge of the sheet metal inward,

thus integrating the outer plate and the inner plate into one.

As the end of 2023, we delivered 9 sets of oilhydraulic hemming machine in total.

The machine is mainly composed of the following parts:

1.Machine transport system: responsible for transporting sheet metal parts;

2.Die: including upper die and lower die, used to press sheet metal parts forming;

3.Hydraulic system: used to drive the upper mold up, down, increase pressure;

4.Mold replacement system: responsible for changing the mold when switching models.